Employees

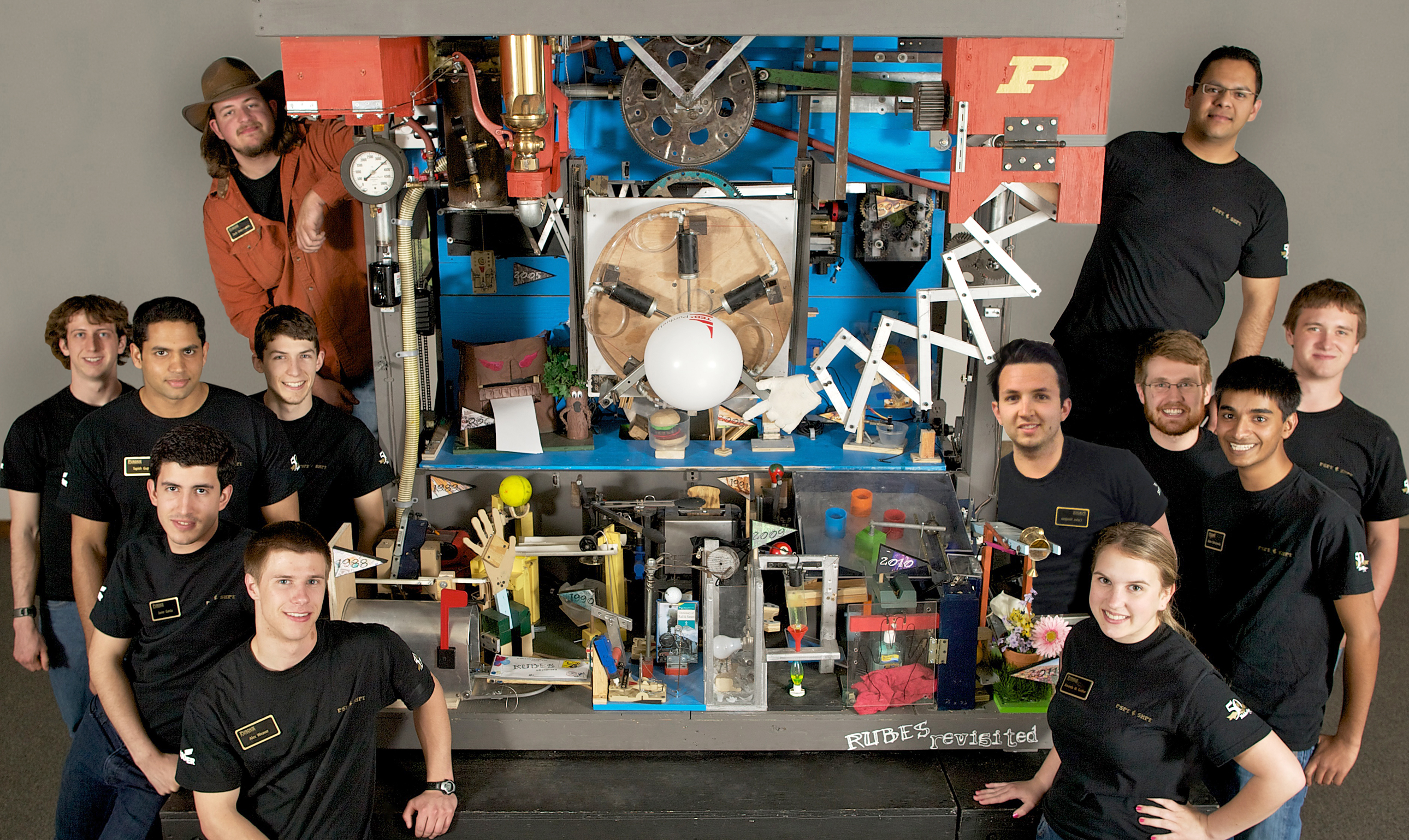

PSPE/SHPE Rube Goldberg Team

Alex and David were both members of the PSPE/SHPE Rube Goldberg team (typically shortened to PSPE Rube Goldberg); Alex from 2009-2013 and David from 2012-2013. It is through PSPE Rube Goldberg that they meet and started to dabble in machining through work in the ME Machine Shop.

Alex can be seen at front left while David is at back left.

Among the many impressive features of this machine were the rotating panels in the back, rotary air engine, and a steam powered piston. The rotating panels were used to increase the # of steps while still giving the audience a view of what is going on. The rotary air engine is similar to a radial piston air plane engine; minus flying and combusting fuel to name a few differences haha. The steam powered piston was put in because its pretty hot and more importantly it made us our schools mascot, BoilerMakers!

Alex and David spent a quite a few hours working on what came to be called the ‘Steamless Engine’, ie the shiny spinning thing in the top middle of the machine. Alex got the idea from a device called a Geneva Gear. A Geneva Gear is a sort of timing device where the center gear spins and an outer gear rotates once for every X number of input revolutions. Alex decided to run the Geneva gear backwards and have the outer gear drive the center gear. The gears where machined on campus in the ME Machine shop. While they can’t be seen in this video there are two large lead weights in the rear of the machine connected to the outer gears through a system of pulleys.